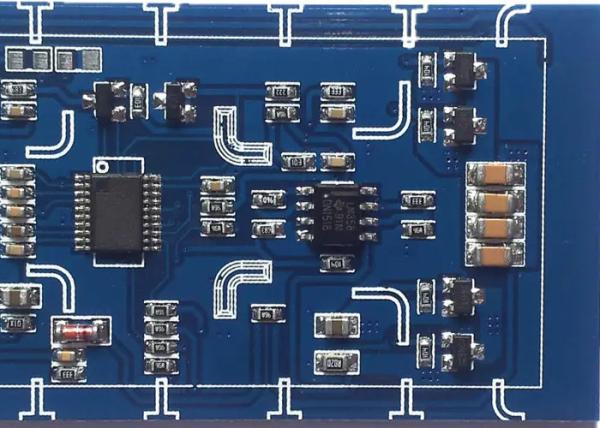

Pcb/Smt/FR-4/Printed Circuit Board/Multilayer board

SMT

SMT patch processing will purchase components according to BOM, BOM

provided by customers and confirm the PMC plan of production. After

the preparatory work is completed, we will start SMT programming,

manufacture laser steel mesh and solder paste printing according to

the SMT process.

The components will be mounted on the circuit board through SMT

mounter, and online AOI automatic optical detection will be carried

out if necessary. After testing, the perfect reflow furnace

temperature curve is set to let the circuit board flow through

reflow welding.

After the necessary IPQC inspection, the DIP material can then be

passed through the circuit board using the DIP process and then

through wave soldering. Then it is time to carry out the necessary

post-furnace process.

After all the above processes are completed, QA will conduct a

comprehensive test to ensure product quality.

Advantages of single layer circuit board

(1) Low cost: The manufacturing cost of single-layer PCB board is

relatively low, because only one layer of copper foil and one layer

of substrate are needed, and the manufacturing process is

relatively simple.

(2) Easy production: Compared with other structural types of PCB

board, the production method of single-layer PCB board is

relatively simple, only need to carry out single-side wiring and

single-layer corrosion, so the production difficulty is low.

(3) High reliability: Single-layer PCB board does not have

multi-layer wiring and connection, so it is not easy to

short-circuit and interference problems, with high reliability.

(4) Suitable for simple circuit: single-layer PCB board is suitable

for simple circuit design, such as LED lights, sound, etc., can

meet most of the low complexity of the circuit requirements.

| Turnkey PCBA | PCB+components sourcing+assembly+package |

| Assembly details | SMT and Thru-hole, ISO lines |

| Lead Time | Prototype: 15 work days. Mass order: 20~25 work days |

| Testing on products | Flying Probe Test, X-ray Inspection, AOI Test, functional test |

| Quantity | Min quantity: 1pcs. Prototype, small order, mass order, all OK |

| Files we need | PCB: Gerber files(CAM, PCB, PCBDOC) |

| Files we need | Components: Bill of Materials(BOM list) |

| Files we need | Assembly: Pick-N-Place file |

| PCB panel Size | Min size: 0.25*0.25 inches(6*6mm) |

| Max size: 20*20 inches(500*500mm) |

| PCB Solder Type | Water Soluble Solder Paste, RoHS lead free |

| Components details | Passive Down to 0201 size |

| Components details | BGA and VFBGA |

| Components details | Leadless Chip Carriers/CSP |

| Components details | Double-sided SMT Assembly |

| Components details | Fine Pitch to 0.8mils |

| Components details | BGA Repair and Reball |

| Components details | Part Removal and Replacement |

| Component package | Cut Tape,Tube,Reels,Loose Parts |

| PCB assembly | Drilling-----Exposure-----Plating-----Etaching &

Stripping-----Punching-----Electrical Testing-----SMT-----Wave

Soldering-----Assembling-----ICT-----Function

Testing-----Temperature & Humidity Testing |

Advantages of multilayer circuit boards

1, the multi-layer circuit board assembly density is high, the size

is small, with the volume of electronic products is getting smaller

and smaller, the function of PCB circuit board is also put forward

higher requirements, the demand for multi-layer circuit board is

also increasing.

2, the selection of multi-layer PCB circuit board laying line is

convenient, the length of the laying line is greatly shortened, the

laying line between the electronic components is reduced, but also

improve the data signal transmission rate.